Production & Operations

At Castle Colour we pride ourselves on producing high quality, fibre based, packaging solutions for a diverse range of customers; from multinational businesses to independent start-up companies.

We have an experienced and dedicated team of professionals who are experts at their craft and highly skilled in a diverse range of manufacturing techniques. Each person is thoroughly trained in their specific role and is encouraged to progress through our business. This means that we often have people who are multi skilled in different disciplines and that broadens their appreciation of what it takes to make your packaging right, time after time.

Our processes

How we operate

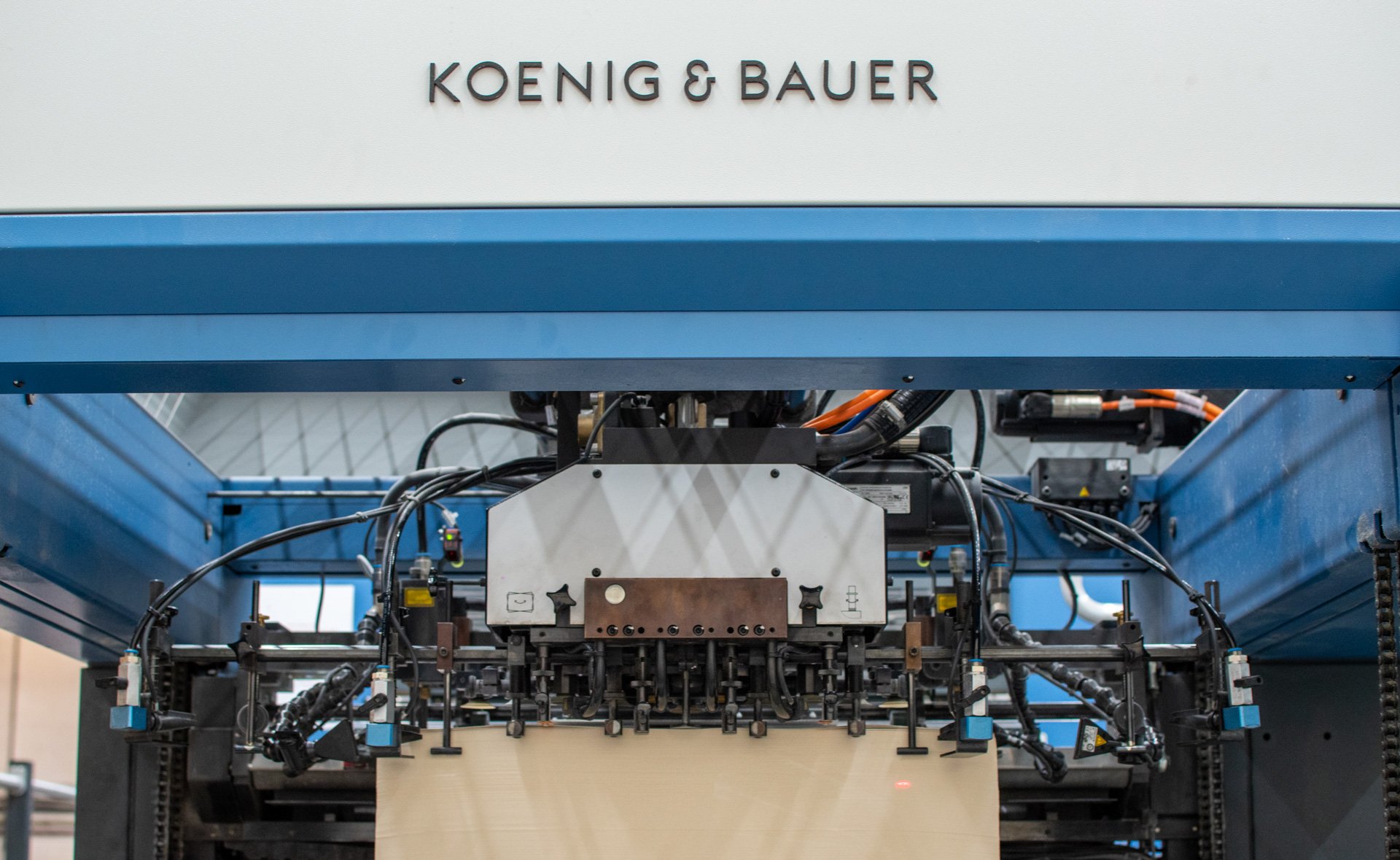

Training and listening are key to how we operate. This means that we regularly invest in additional training for our teams and additional services to further support our operational capabilities. We are unusual because we carry out nearly every operation on our site - from initial constructional design, to pre-press file preparation, short run digital mock ups, printing, die cutting, gluing, embossing, window patching, foiling, banding and storage. This gives us greater control, flexibility and effectiveness when producing your packaging.

Every year we invest, and this keeps us at the forefront of operational capability and efficiency.

Our Techniques

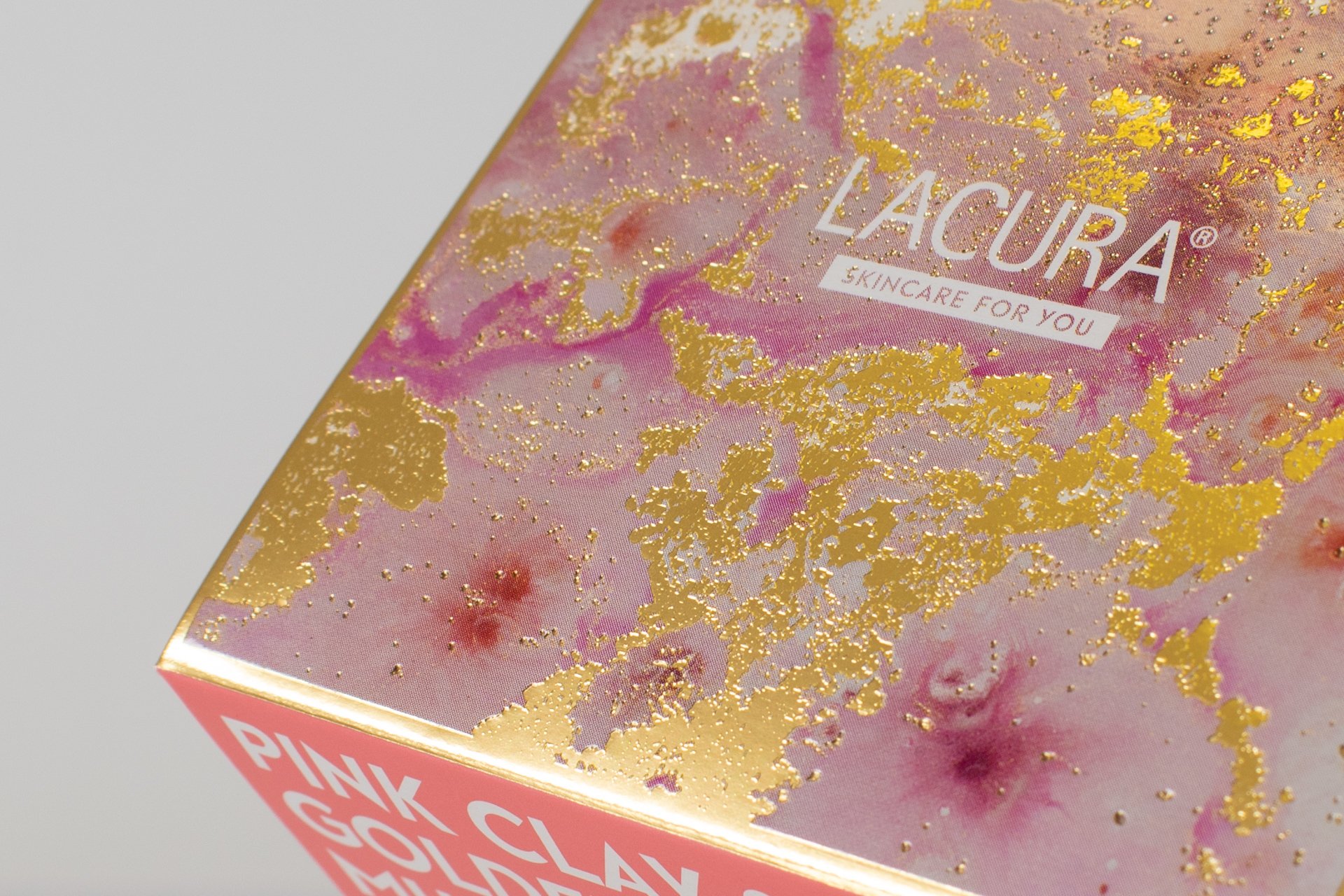

From vibrant colours and intricate patterns to unique textures and finishes, we employ a wide array of techniques to ensure that your packaging captures attention and leaves a lasting impression

Whether it's the subtle elegance of embossing and debossing, the eye-catching brilliance of foil stamping, or the tactile appeal of spot UV coating, our range of effects enhances the visual and sensory experience of your packaging. Our technical team have seen, and mastered, it all.

In each case our operations teams work to a simple formula: make your packaging once, make it right, make it the best.